RESOLTECH 1800

Hardeners 1803, 1805, 1807 & 1808

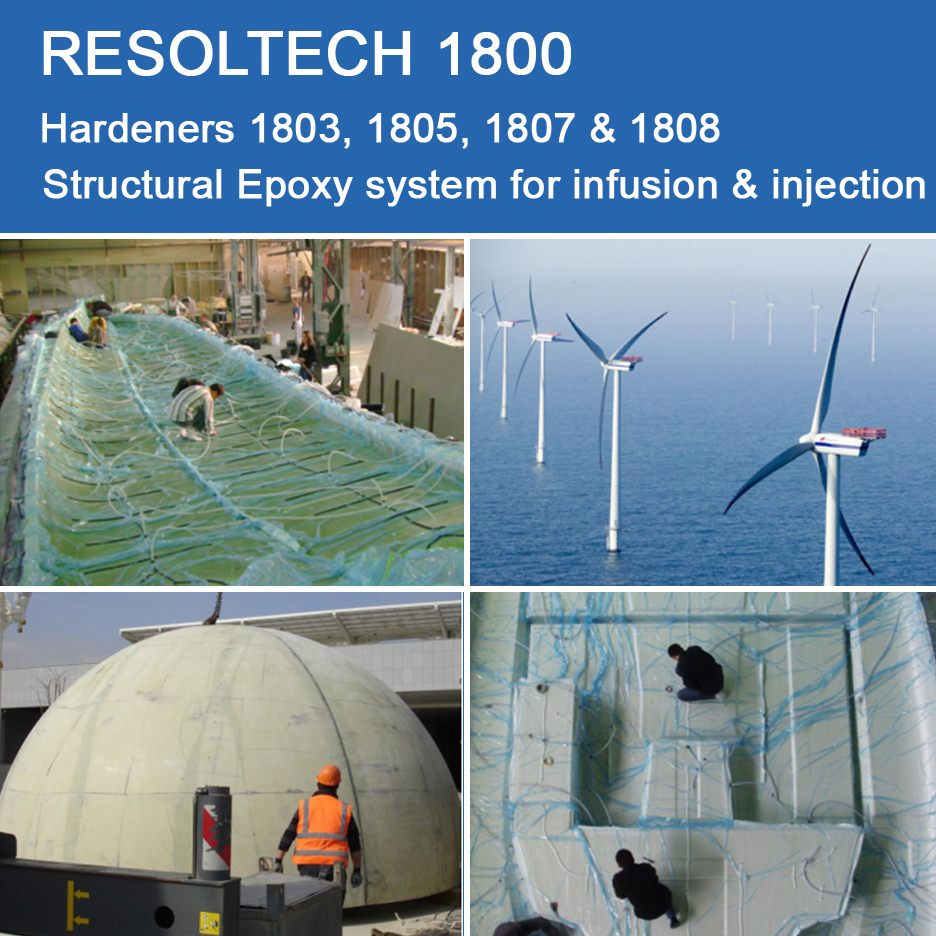

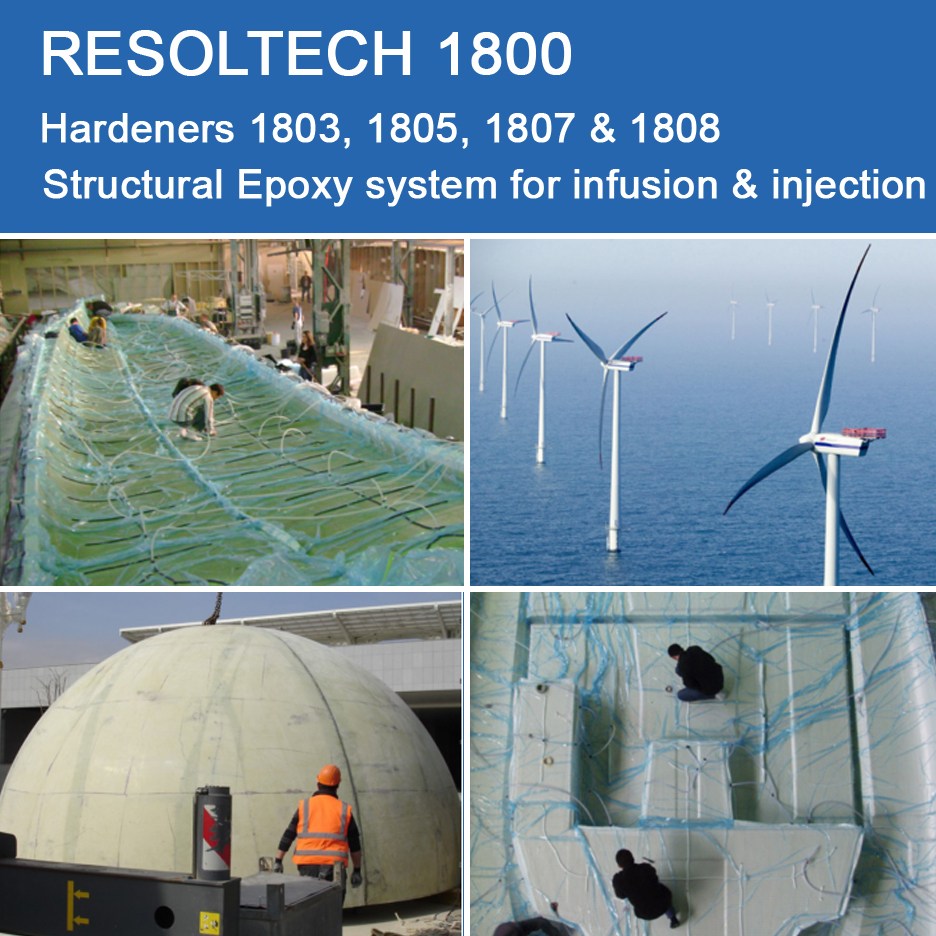

Structural Epoxy system for infusion & injection

- Adjustable pot life from 18min to 7h

- Very low viscosity and high wetting power

- TG up to 120ºC depending on hardener used

- Excellent cross linking properties even at low post-curing temperatures

RESOLTECH 1800 is an advanced infusion and injection epoxy resin system with an extremely low viscosity for fast and safe wet out by infusion and injection.

It features high mechanical properties, a service temperature up to 130°C and up to 7h of infusion or injection time.

The constant low viscosity right until gel time offers reliable impregnation and air release throughout the infusion or injection process.

This system has excellent cross linking properties and enables to release from plugs even after low post curing temperatures at 40ºC.

It is suitable for both tooling and parts manufacturing. Typical applications include large marine structures, wind turbine blades, moulds for prepreg production.

Monolithic carbon fibre infusions may be performed with fiber ratios of over 68% with 0,4% porosity.

The superior interlaminar shear strength of this system is one of its key advantages with its improved health and safety formulation following the latest EU regulation (CE) n°453/2010.

- DS - 1800 - 180X.pdfFilesize: 863.9 kB